➤ Introduction

Behind every successful custom backpack is a smart choice of material. Whether for school, outdoor hiking, or corporate promotion, fabrics directly influence durability, comfort, weight, and even brand value. For buyers working with a backpack manufacturer, understanding key fabrics is essential to making informed decisions. This article explores the most common and reliable fabrics used in backpacks, highlighting their pros, cons, and best uses.

➤ 1. Polyester: Affordable and Versatile

Polyester remains one of the most widely used backpack fabrics, thanks to its affordability and adaptability. It is lightweight, water-resistant to a certain degree, and available in countless colors and finishes. For promotional or wholesale orders, polyester helps keep costs reasonable while still offering decent performance.

Factories often recommend polyester for school bags and casual daypacks. However, for heavy-duty or luxury backpacks, polyester may not provide the same strength as nylon. Buyers should carefully match the material with their target customers’ needs.

➤ 2. Nylon: Strong and Durable

Nylon is the go-to material for high-performance backpacks. Known for its abrasion resistance and strength, nylon can withstand tough outdoor conditions. Variants such as 420D or 1680D nylon are particularly valued in the hiking and tactical backpack markets.

A professional backpack factory will often suggest nylon when clients need products that last under heavy use. The material also accepts coatings like PU (polyurethane) for added waterproofing, making it a premium choice for outdoor brands.

➤ 3. Canvas: Classic and Eco-Friendly Appeal

Canvas offers a traditional, rugged look with excellent durability. Originally made from cotton, modern canvas can be blended with polyester for greater resistance to tearing and moisture. It is popular in vintage rucksacks, lifestyle backpacks, and eco-friendly collections.

Buyers who want a sustainable option often request organic cotton canvas, which appeals to environmentally conscious consumers. A custom backpack manufacturer can apply stone washing, wax treatments, or color dyeing to give canvas backpacks a unique appearance.

➤ 4. Leather Accents: Premium Branding

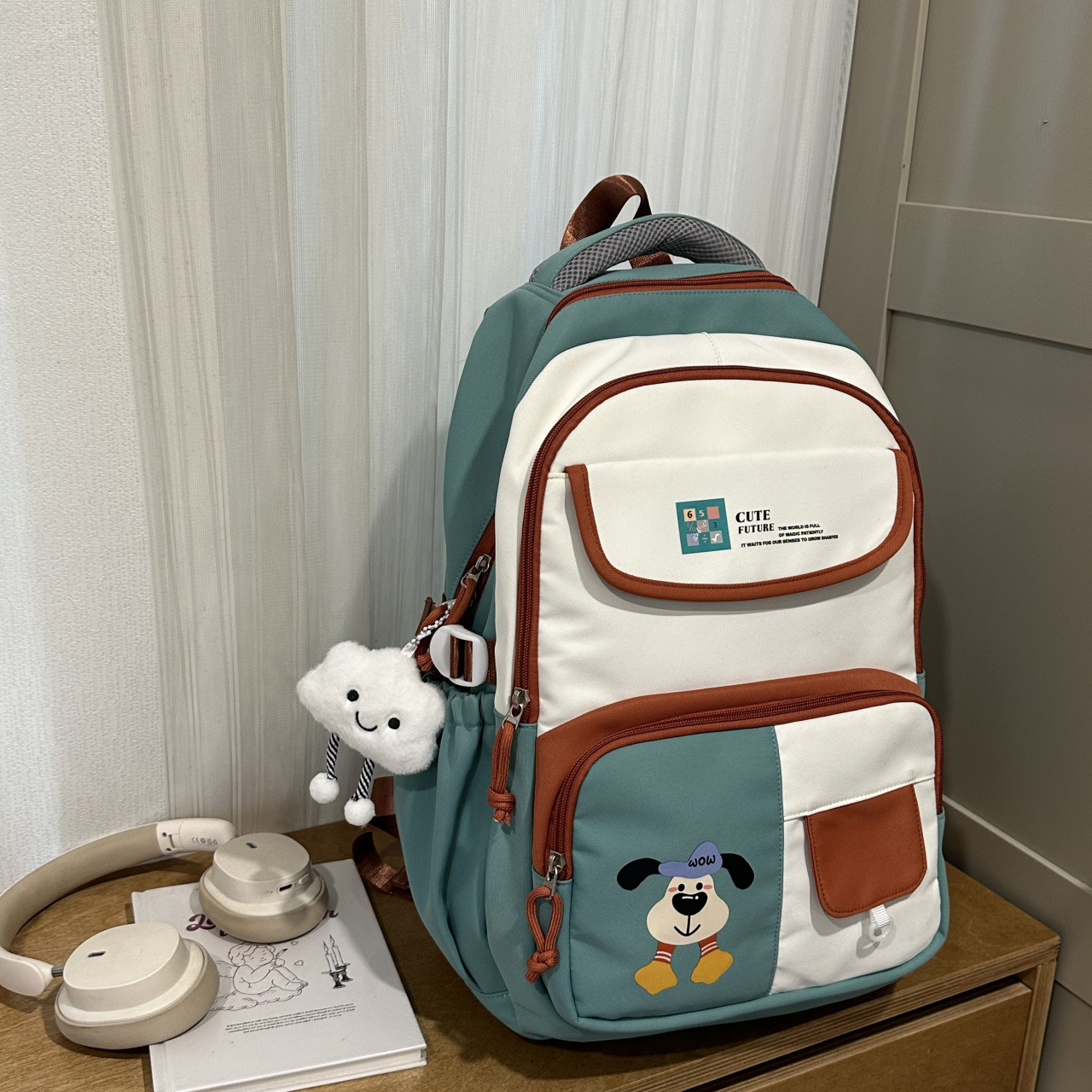

While few backpacks are made entirely of leather due to weight and cost, leather accents on straps, zippers, or logos can elevate the product. Genuine leather conveys luxury, while PU (synthetic) leather offers a cost-effective alternative with a similar look.

Factories often encourage mixing fabrics—canvas or nylon for structure, with leather for branding points. This approach allows wholesalers and retailers to market backpacks as both functional and stylish.

➤ 5. Ripstop Fabrics: Lightweight but Strong

Ripstop refers to woven fabrics reinforced with stronger threads, creating a grid pattern that prevents tears from spreading. This makes ripstop nylon or polyester ideal for travel, camping, and sports backpacks.

For businesses aiming to position themselves in the performance market, suppliers often recommend ripstop. It combines lightness with resilience, offering an attractive solution for customers who demand durability without unnecessary bulk.

➤ 6. Eco-Friendly and Recycled Materials

Sustainability is no longer a trend but a requirement in many global markets. Recycled PET (rPET), made from plastic bottles, is increasingly used in backpack production. It reduces environmental impact while delivering similar performance to virgin polyester.

Forward-thinking factories invest in eco-material sourcing to meet demand from European and US buyers. Brands using rPET in custom backpacks can highlight their commitment to the environment, attracting eco-conscious customers and retailers.

➤ 7. Waterproof Coatings and Linings

Besides the outer fabric, coatings and linings play a major role in performance. PU (polyurethane) and PVC coatings add water resistance, while TPU laminates offer premium waterproofing. Inside, polyester linings protect the structure and improve usability.

A reliable backpack manufacturer ensures coatings are tested for durability, avoiding peeling or fading after a few months. Buyers should confirm the coating type during sampling to match the level of water resistance required.

➤ 8. Choosing the Right Fabric for Your Market

Every material has strengths and limitations. Polyester keeps costs low for promotional giveaways. Nylon excels in outdoor and tactical use. Canvas appeals to lifestyle and eco-conscious markets. Leather accents create premium designs, while ripstop and recycled fabrics offer specialized solutions.

When working with a backpack factory, discuss your target customers and intended use before finalizing fabrics. The right choice ensures product success and customer satisfaction.

➤ Conclusion

Materials define the value of a backpack. From polyester’s versatility to nylon’s strength, from canvas’s timeless charm to eco-friendly rPET, each fabric tells a story. By understanding these options, buyers can make smarter choices, ensuring their custom backpacks meet market expectations.

Partnering with a reliable backpack manufacturer or supplier guarantees that fabric selection, sampling, and mass production align with your brand goals. In a crowded market, the difference between an average and an exceptional backpack often comes down to fabric selection.